Knowing now that the computer itself was functional, I set off to repair the connections between the Main Logic Board, Floppy Controller Card , and RS232 Card. As shown in a previous post, the flexible flat ribbon cable that connected between the the main logic board and the two daughter boards had deteriorated to the point of no return. A previous owner had attempted to shove one of the cables into the connector failing miserably.

Based on the information that these cables are few and far between and quite hard/expensive to come by, I opted for a repair that would eliminate them altogether. This option is replacing the 4 flat ribbon connectors with pin headers and using short IDC cables to connect between them.

I began by removing the main logic board and two daughter boards from the chassis. When doing this, be sure to use an anti-static strap to prevent any chance of static damage to the boards. Once the boards were removed, I proceeded to remove the flat ribbon cable connectors. The easiest way I found to do this was to snip the plastic at each end of the connector then remove it leaving the pins exposed. Alternately, you can rock the connector back and forth until the pins fatigue and break, but you have less left to grab during removal. This is what I was left with once the plastic was removed.

I then proceeded to one by one, grab a pin with tweezers, heat the solder, and remove the pin. MAKE SURE THE SOLDER IS FLUID BEFORE PULLING ON THE PIN OTHERWISE TRACES COULD PULL UP WITH THE SOLDER! I AM NOT RESPONSIBLE IF YOU DAMAGE YOUR BOARD DURING THIS PROCESS. PLEASE EXCERSIZE CAUTION.

I then proceeded to one by one, grab a pin with tweezers, heat the solder, and remove the pin. MAKE SURE THE SOLDER IS FLUID BEFORE PULLING ON THE PIN OTHERWISE TRACES COULD PULL UP WITH THE SOLDER! I AM NOT RESPONSIBLE IF YOU DAMAGE YOUR BOARD DURING THIS PROCESS. PLEASE EXCERSIZE CAUTION.

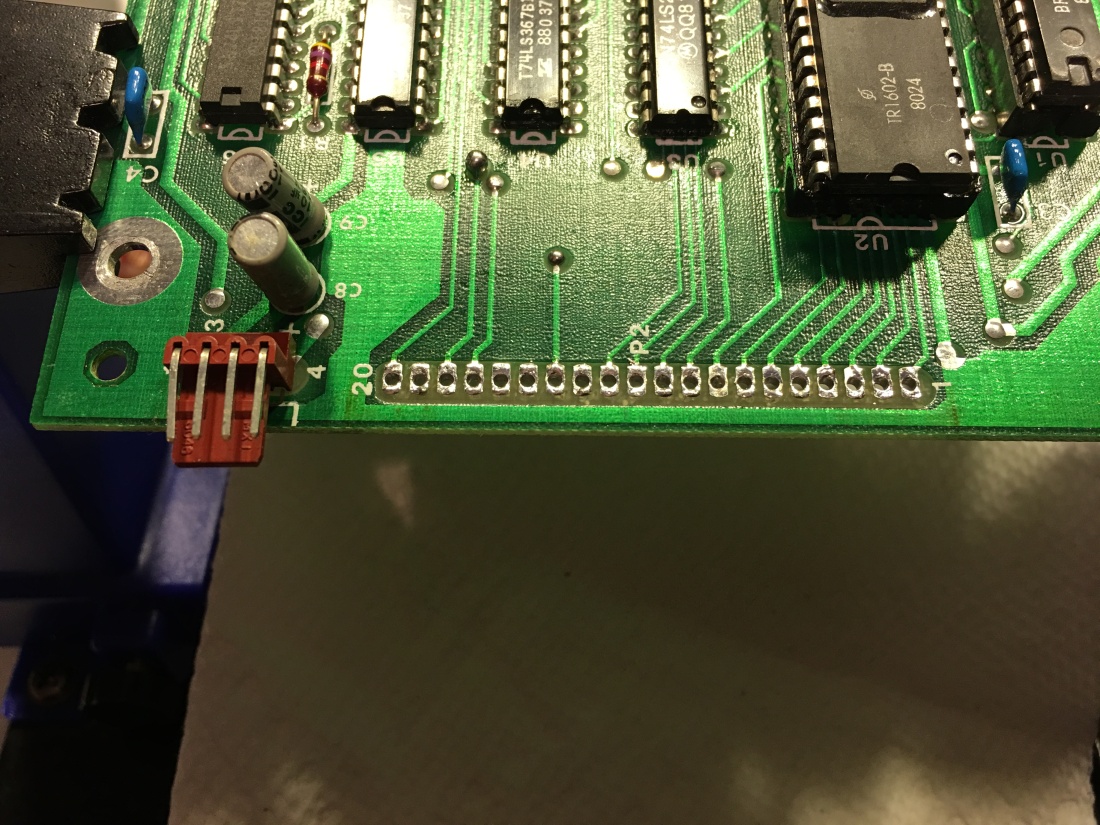

Once all the pins were removed, I added fresh solder to all the locations, then one by one remove the solder with a solder sucker. Any remaining solder was removed with solder wick. The result after removal was a nice clean row of open holes ready for pin header installation.

Once all the connections were clean and free of solder, I proceeded to install pin headers in all the locations.

Once all the connections were clean and free of solder, I proceeded to install pin headers in all the locations.

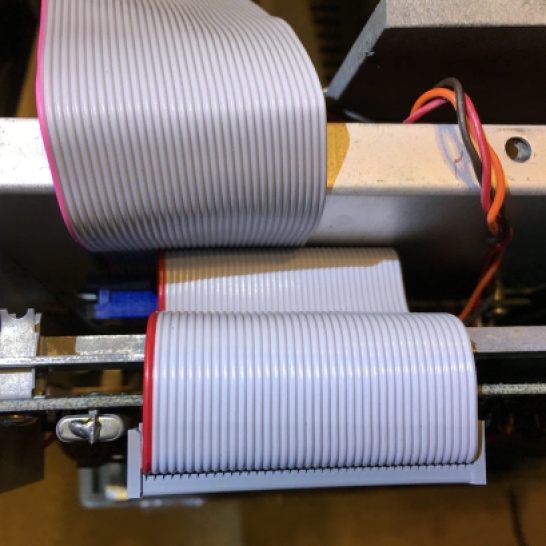

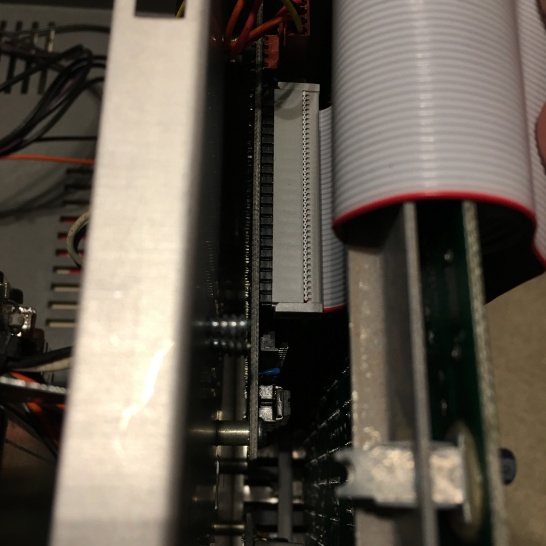

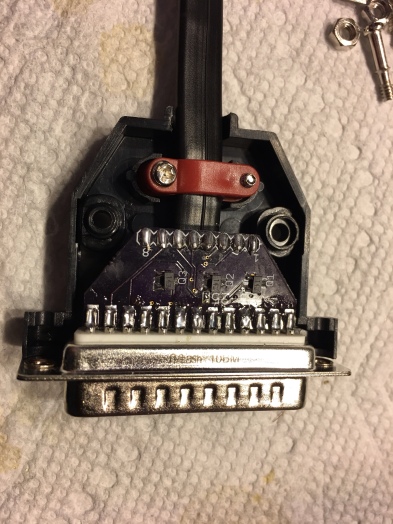

Then all that was left to do was to connect the boards with short 40 pin IDC ribbon cables. The key to this is to be sure and use the same row of holes on each end thus using 1/2 of the wires in the cable. Here are some images of the cables connected.

Then all that was left to do was to connect the boards with short 40 pin IDC ribbon cables. The key to this is to be sure and use the same row of holes on each end thus using 1/2 of the wires in the cable. Here are some images of the cables connected.

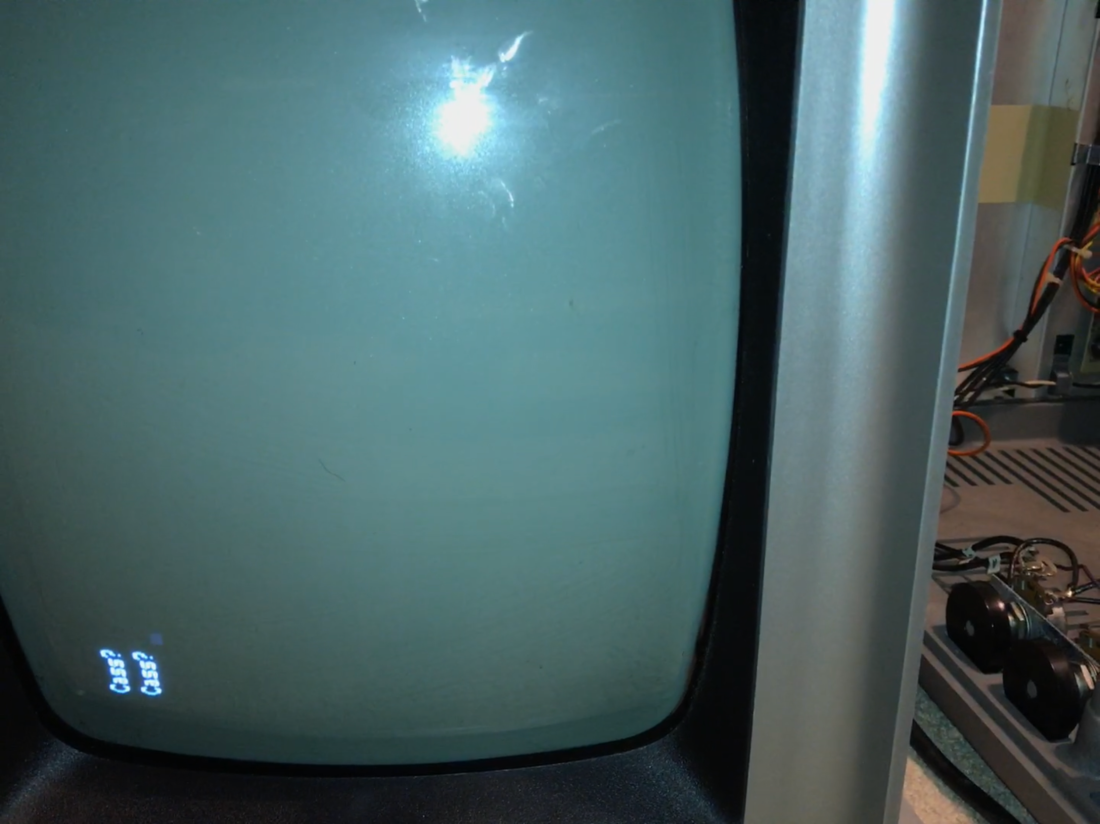

Now that I had all the connections between the boards modernized and reliable, I buttoned up the back end and began to focus on the drives.

In the next post, I will outline my progress by showing the installation of a GOTEK floppy drive emulator along side a double sided 5 1/4″ floppy drive in the drive 0 and 1 position with a toggle switch that will allow switching which drive is 0 and which is 1 allowing to boot from either.

To be continued…

To be continued…